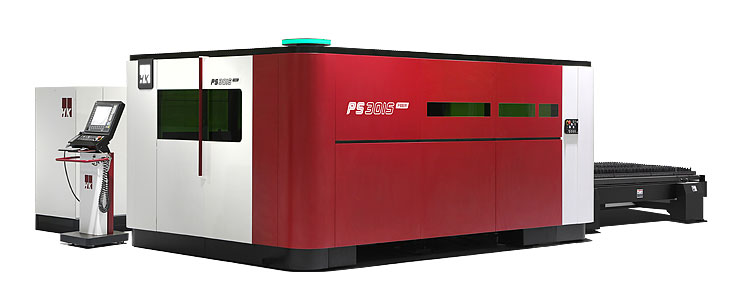

Laser Cutting Machine 3mm Steel

Laser cutting machines are divided into two types based upon laser sources: fiber laser machines and CO2 machine.

The maintenance-free industrial laser cutting system boasts outstanding technical advantages, ultralow power consumption, reduced operating cost, and repeatable laser positioning performance. It sets a new standard in complex pattern cutting and quality inspection.